Metal Corrosion – Generalized Corrosion & Prevention using Protective Coatings

This article is intends to discuss:

- Corrosion can happen naturally when the metal surface is exposed to corrosive surroundings.

- Corrosion can be classified into two categories: generalized and localized corrosion.

- Anti-corrosion protective coating is one of the most effective solution to corrosion problems.

What is Metal Corrosion?

Corrosion is a natural process that usually happens on metals when the surface is exposed to corrosive surroundings, the corrosion process speeds up when there is exposure to warm environments, acids and salts. Most of the metals used in the industries are susceptible to corrosion and that threatens the lifespan of assets, which can end up contributing huge losses and operational downtime.

Corrosion can be classified into two broad categories: generalized and localized. This article will explore about generalized corrosion and how the application of protective coating can be a lifesaver for corrosion problems.

Generalized Corrosion

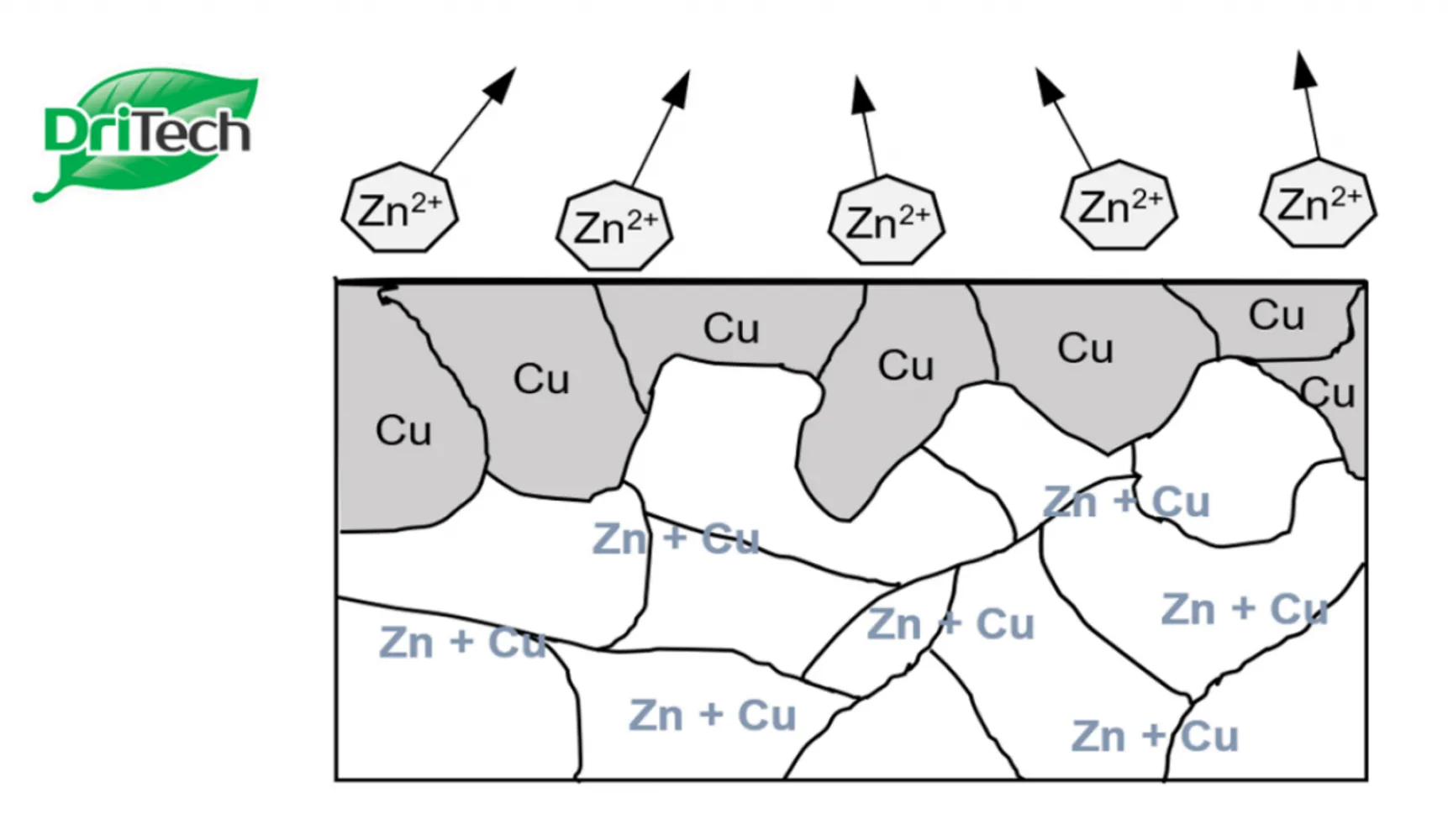

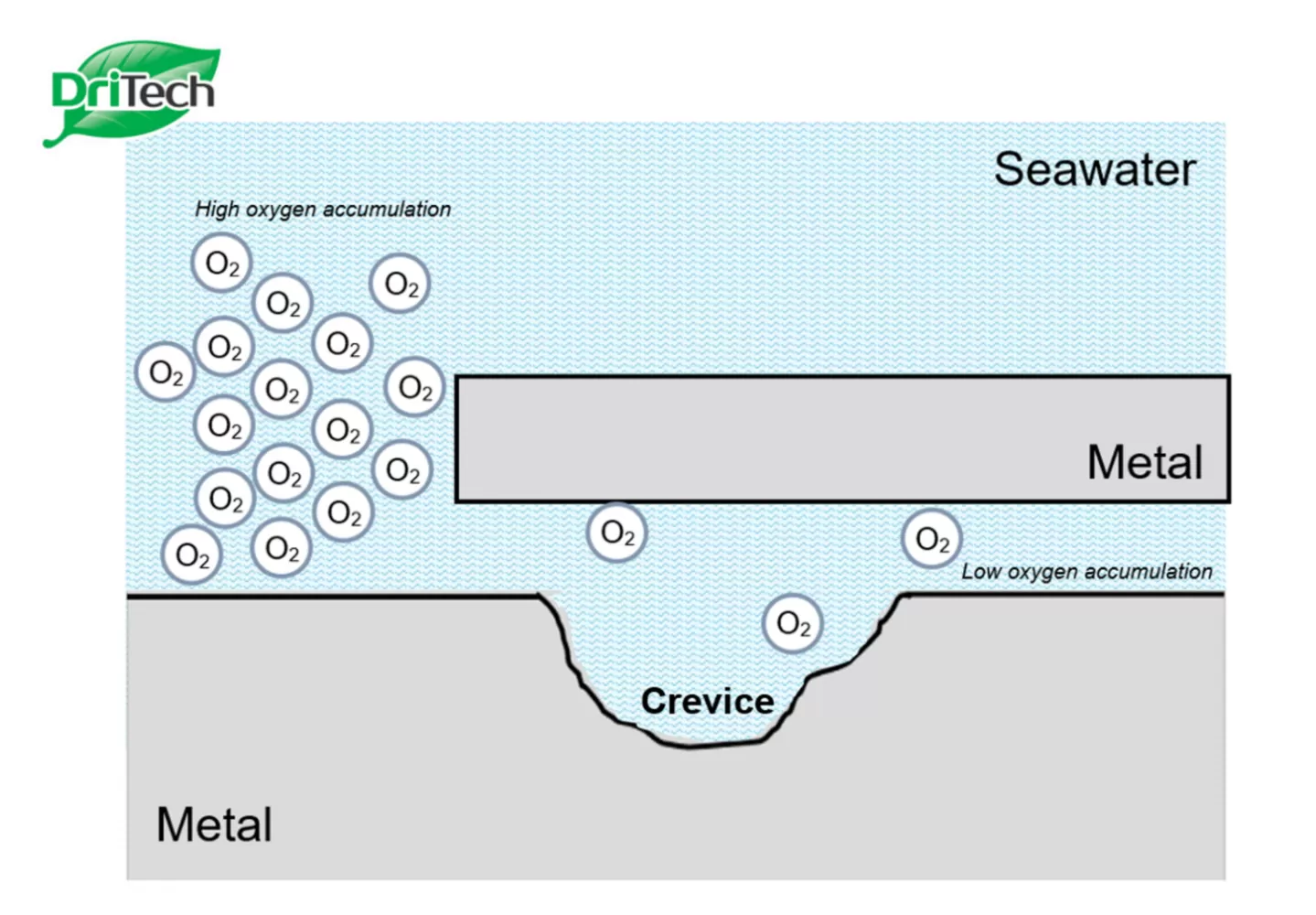

Generalized corrosion is also known as uniform attack corrosion. This type of corrosion is highly reliable on climatic conditions and the makeup of the material; hence, it usually happens at a slow rate. This type of corrosion is triggered by an electrochemical reaction of anodic and cathodic process which appears over the surface that will eventually result in thinning of the metal until it fails.

Reduction of dissolved oxygen is the primary cause for the corrosion to occur in the natural environment. The process involves cathodic process that which shown as follow reaction:

O2 + 2H2O + 4e = 4OH–

For acidic environment, the cathodic reaction involves reduction of hydrogen ions:

2H+ + 2e = H2

It was known as ‘uniform’ corrosion due to the equal exposure and distribution of metal surface and cathodic reactants, hence loss of dimension occur uniformly.

While it can occur on any metal surfaces in various environmental conditions, it is fairly predictable and easily detected if occur, hence it will only cause minor issues.

Corrosion Prevention & Control

Protective coatings are formulated to provide protection for materials to withstand corrosion, abrasion and all kinds of degradation. Selecting an appropriate coating system depends on many variables such as the type of materials to be coated, the quality required, abrasion and chemical resistance and the environment exposed.

DriTech Chemicals provides a wide range of protective coatings products for corrosion control.

| Product | Primer/ Substrate Preparation |

Body Coat (Non-UV Resistant) |

Body Coat (UV Resistant) |

Top Coat (UV Resistant) |

| Dri-Gard MP 10 Single-pack polyvinyl butyral primer |

/ | |||

| Dri-Gard RC 30 Rust Converter |

/ | |||

| Dri-Gard RC 50 Water-based rust converter |

/ | |||

| Dri-Gard ZN 45/ZN 80 Single-pack zinc-rich primer |

/ | |||

| Dri-Gard ZN 90 Epoxy zinc-rich primer |

/ | |||

| Dri-Gard EP 1800 Epoxy novolac coating |

/ | |||

| Dri-Gard MIO 52/MIO 60 Micaceous iron oxide (MIO) epoxy coating |

/ | |||

| Dri-Gard RE 4434 Mastic epoxy coating |

/ | |||

| Dri-Gard TF 320 Tar-free epoxy coating |

/ | |||

| Dri-Gard TZ 300/TZ 300GF Solvent-free epoxy coating |

/ | |||

| Dri-Gard SW 100/SW 180 Coal tar epoxy coating |

/ | |||

| Dri-Gard UV 920 Aliphatic polyurethane |

/ | |||

| Dri-Gard CF 900 Methylmethacrylate (MMA) coating |

/ | |||

| Dri-Gard MF 50 Quick drying aluminium paint |

/ |

Table 1: Dri-Gard Protective Coating for Metal/Steel Substrates for Corrosion Protection

Please contact us for more information on appropriate protective coating systems for your structures.

by Oh Hui Xuan

[27 January 2022]

15 Dec 2022